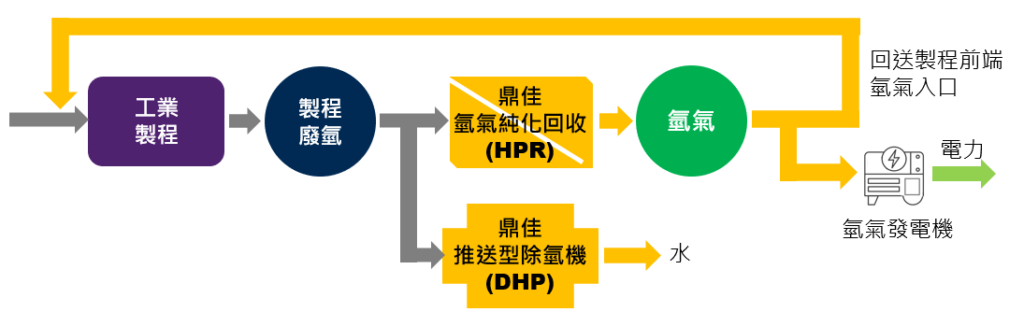

製程廢氫處理

鼎佳的氫氣純化回收(HPR, Hydrogen Purification & Recycling)方案可解決目前業界因製程廢氫無法回收,而需排放拋棄的問題,純化後的氫氣可以回收給原製程使用、或是用來發電。

氫氣純化回收(HPR)方案包含二種設備: 電化學氫氣純化器ECHP (Electrochemical Hydrogen Purifier)以及多孔陶瓷吸附純化器PCAP (Porous Ceramics Adsorbent Purifier),兩者均可在常壓下工作,無須對氫氣加壓,是非常安全的解決方案。

ECHP用來去除氮氣,PCAP則是用來去除氮氣以外的其他物質例如水、氧、氨、揮發性有機化合物(VOCs)…等;依客戶之使用條件,可以單獨或合併使用。

針對無回收效益而需將製程廢氫排放或燃燒導致工安顧慮以及溫室氣體排放的環保問題,鼎佳提供DHP推送型除氫機,用於排放廢氫之管線出口,讓氫氣先氧化至安全範圍之後再排放,氧化過程產生的熱可回收利用。鼎佳DHP採用自行開發之低溫氫氣氧化(LTHO, Low Temperature Hydrogen Oxidation)技術、以無火焰、零排放的運作方式將廢氫轉化為水,讓殘餘氫氣濃度低於4000ppm(10% LEL)、符合安全標準。

氫氣是自然界分子量最小的物質,很容易經由設備或管線的微小縫隙洩漏導致作業場所氫氣蓄積而產生爆炸的危險,鼎佳DHC對流型除氫器採用LTHO技術,無需用電,可用於常態性循環去除空間中的洩漏氫氣,避免場所中因通風不良或設備故障導致的氫氣蓄積,以提升安全。

燃料電池